SULFUR RECOVERY UNIT SOLUTIONS (SRU)

High Temperature Thermocouples and Pyrometers

Thermocouple is designed for the primary purpose of reliably protecting a vessel and its refractory lining from excessive temperatures. The HTP provides long-term accuracy and reliability in sulfur processing service.

The design of the HTP is a result of careful attention to design detail, more than 45 years of experience, and numerous field installations. The thermocouple junction is isolated from corrosive and invasive gases by using a constant low-flow flush gas circulating across the junction. The flush gas is kept at a pressure higher than the internal reactor pressure to mitigate the migration of process gases through the primary thermowell, body or seals. Process gases that enter are carried away by the flush gas. The metered flush gas flow has an insignificant effect on the accuracy of the temperature measurement.

Liquid Sulfur Pump

Pumps are designed to maximize wear life in some of the world’s most corrosive industrial applications while simplifying maintenance through their streamlined designs. This has significantly reduced the number of parts compared to previous pumps, without compromising their performance.

Reaction Furnace Burner

The reaction furnace is the heart of the Sulfur Recovery Unit (SRU), initiating the conversion of H2S and other sulfur-bearing compounds to elemental sulfur. … The reaction is highly exothermic and is typically controlled to a temperature between 2200-2700°F (1200-1500°C).

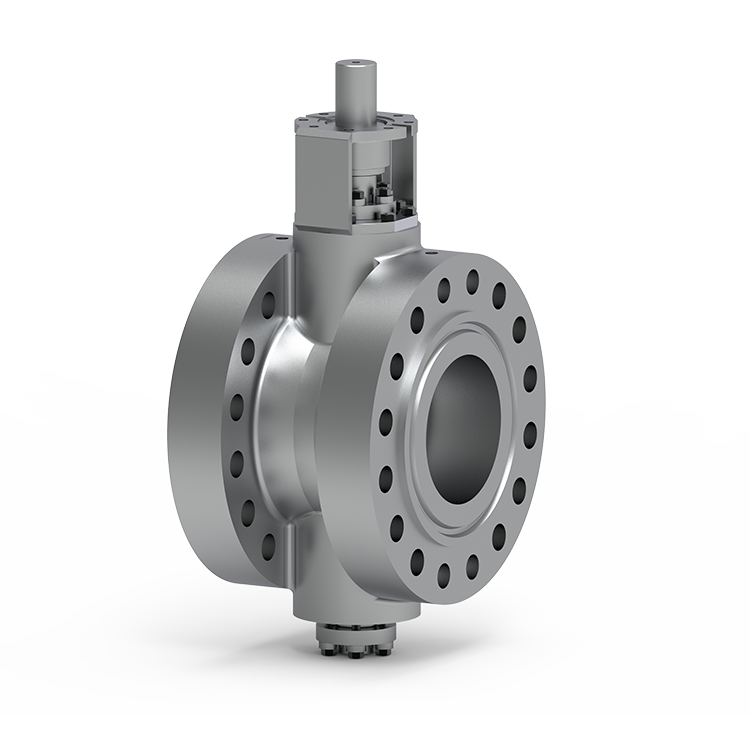

High Pressure Valves

The reaction furnace is the heart of the Sulfur Recovery Unit (SRU), initiating the conversion of H2S and other sulfur-bearing compounds to elemental sulfur. … The reaction is highly exothermic and is typically controlled to a temperature between 2200-2700°F (1200-1500°C).

Refractory

provides high quality, low-cost inert ceramic and alumina support media worldwide.

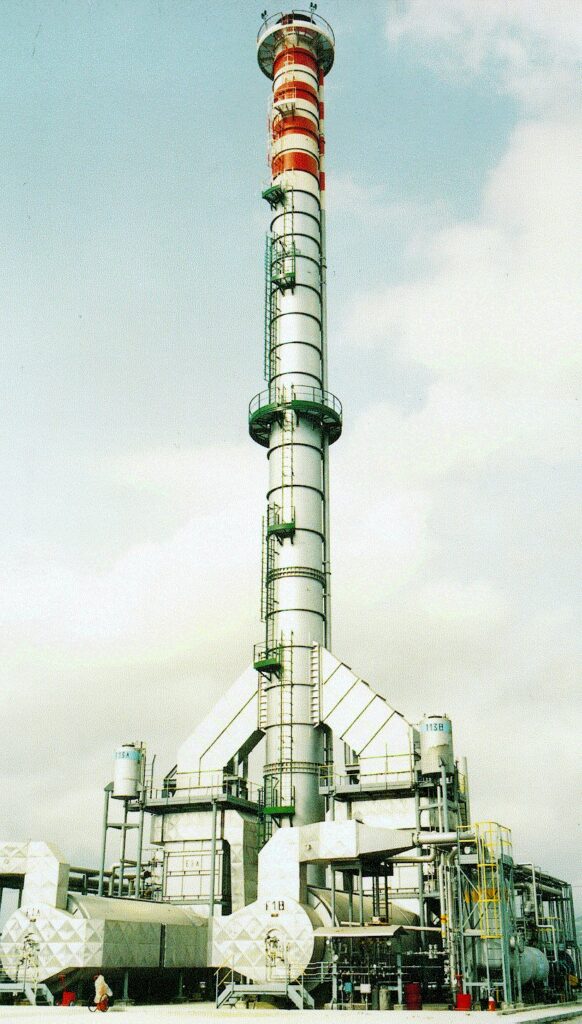

Gas Flares,Incinerators

A gas flare, alternatively known as a flare stack, flare boom, ground flare, or flare pit is a gas combustion device used in industrial plants such as petroleum refineries, chemical plants and natural gas processing plants. They are also common at oil or gas extraction sites having oil wells, gas wells, offshore oil and gas rigs and landfills.

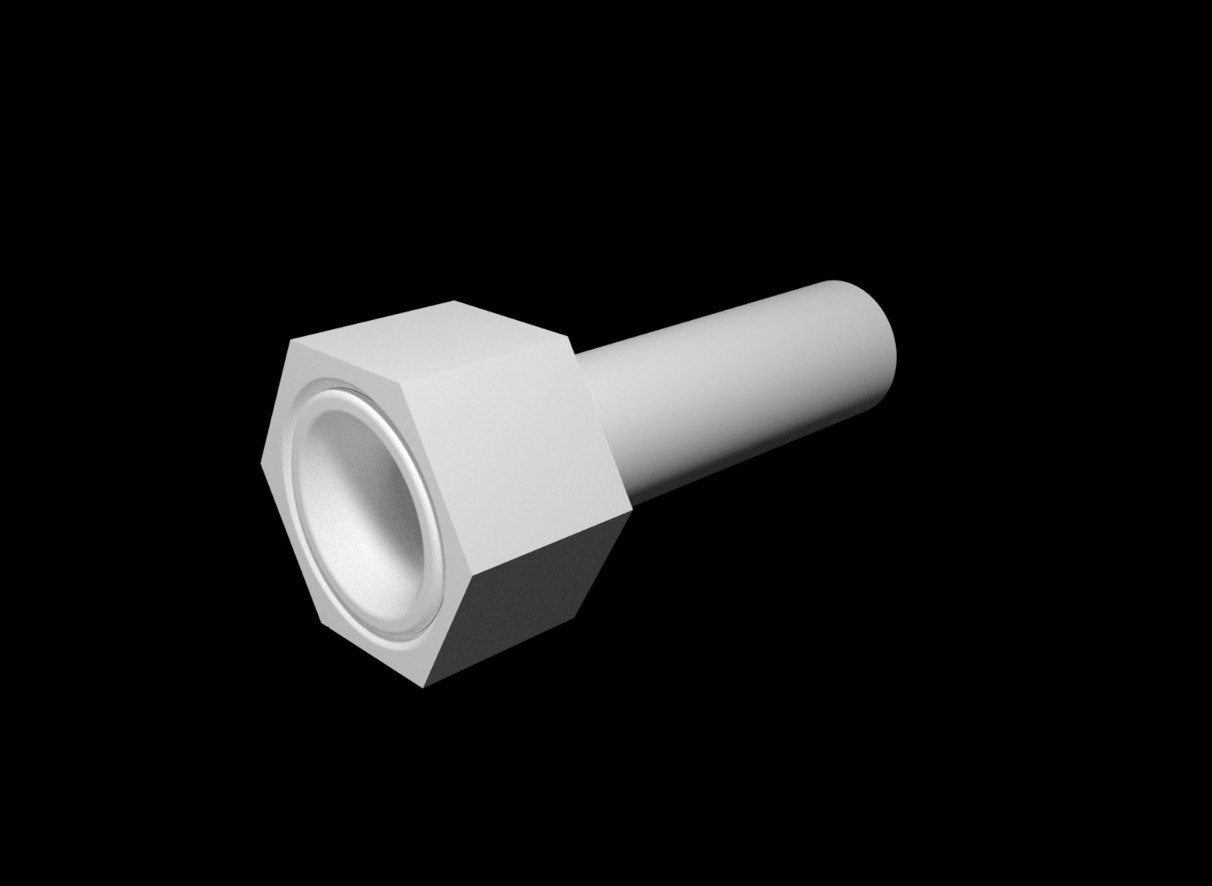

Ceramics Ferrules for Tube Sheets

Enjoying decades of experience, is proud of providing a large variety of products and services mainly in the field of tubesheet protection. We supply ferrules (completed with paper and gasket) to a very large range of Industrial plants, mainly Sulphur Recovery Units (Reaction Furnace and Incinerator), Sulphuric Acid Plants and so on. As a part of our technical services, by carefully studying your plant conditions and parameters, we make sure to provide you with the right ferrule design for your specific application. Our services also include troubleshooting for boiler-related problems; in-depth thermal studies including CFD’s, and last but not least, installation assistance and supervision.

SRU ,TGU Catalysts and Bed Support

provides high quality, low-cost inert ceramic and alumina support media worldwide.

Our Partners