MATERIAL HANDLING SOLUTIONS

INDURAD SYSTEMS

Our goal is to enhance safety and efficiency in Oil and Gas, Mining and Bulk Material handling. We achieve this by leveraging Indurad radar sensors and solution framework.

As Indurad Systems supplier in UAE .We SYSTEMS EQUIPMENT dedicated to revolutionising asset efficiency and safety through innovative radar technology and software solutions. Our solutions will help enhance connectivity and safety, minimise downtime in the mining and plant industries, and ultimately achieve optimised performance and sustainable operational excellence.

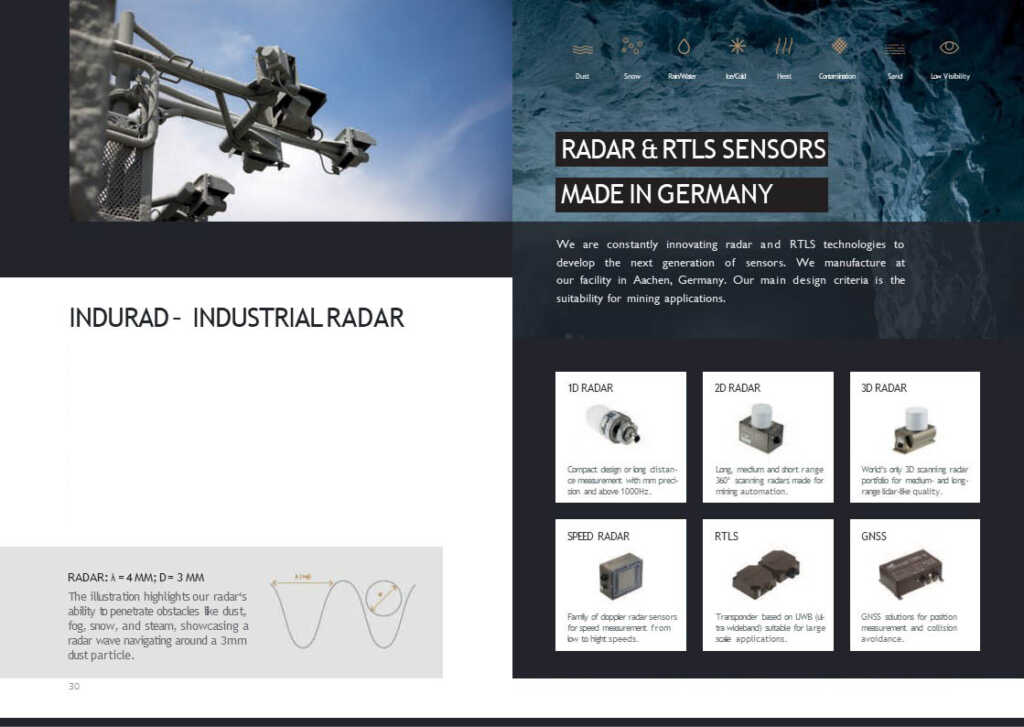

We are constantly innovating radar and RTLS technologies to develop the next generation of sensors. We manufacture at our facility in Aachen, Germany. Our main design criteria is the suitability for mining applications.

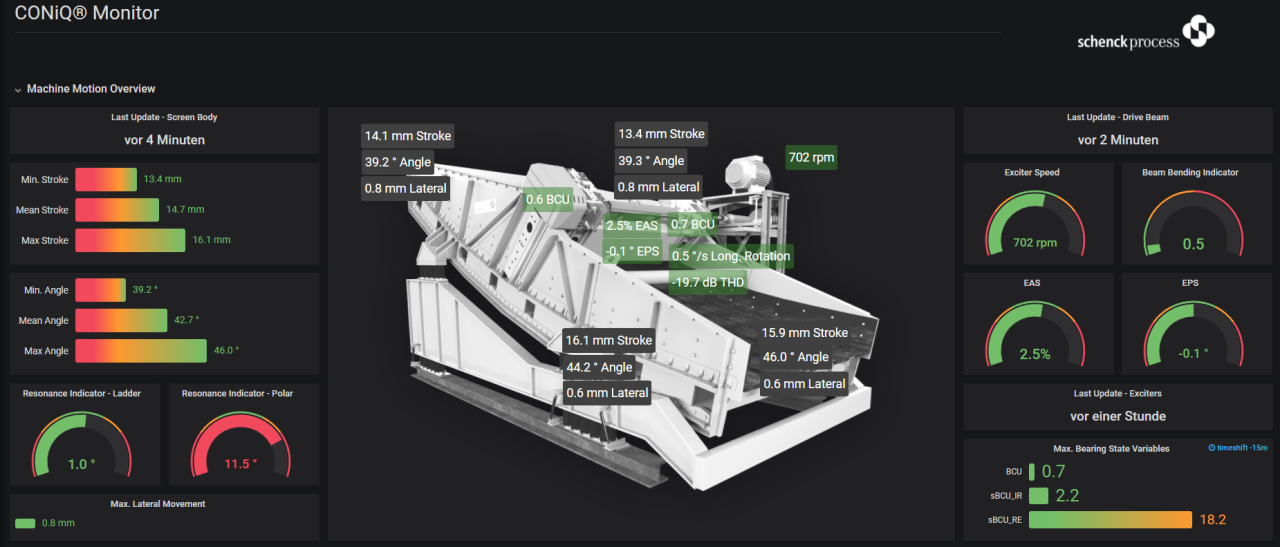

SCHENK PROCESS Qlar

A global technology provider, leading the way with precision, accuracy, and premium quality in material processing. Our product range includes solutions for industrial weighing, feeding, conveying, milling and grinding, and related digital applications of the CONiQ product family.

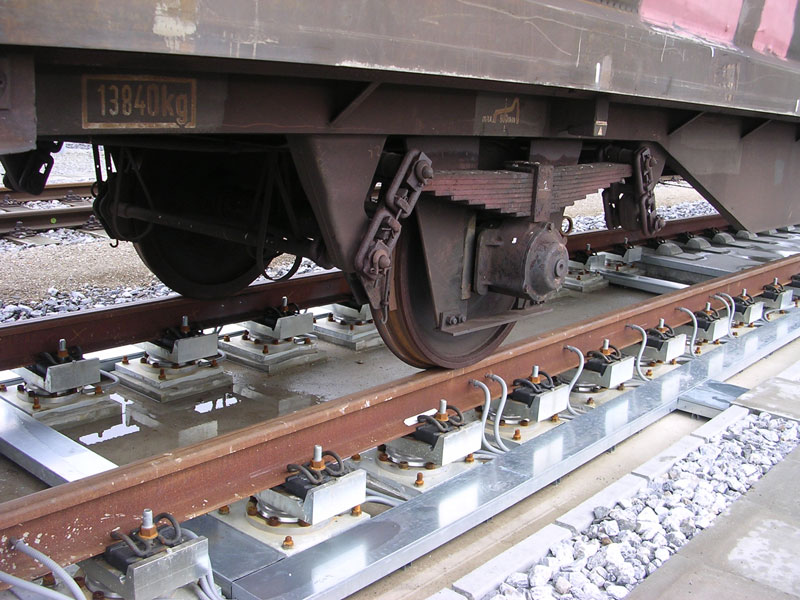

Schenk Process QLAR deals with Industrial weighing, pulverizing and classification, dense phase conveyors, mills, grinders, Pneumatic conveyors, Chain conveyors, mixing machines, metal production, plastics, chemicals, cement, condition monitoring, feeders, and train loading

As a SCHENK PROCESS (QLAR ) SUPPLIER IN UAE SYSTEMS EQUIPMENT .We deals with Train Loading ,Industrial Weighing etc..

INDUSTRIAL RADAR SENSORS IN UAE - INDURAD

RADAR & RTLS SENSORS

we SYSTEMS EQUIPMENT as INDUSTRIAL RADAR SENSORS SUPPLIER IN UAE - INDURAD . Since inventing the first 2D radar for industrial use, the iDRR (indurad DualRangeRadar), in 2008, in INDURAD technology and product range have significantly advanced. Today, INDURAD offer a comprehensive array of radar sensors that boost productivity and sustainability for our customers, under any environmental condition.

Indurad product range now includes RTLS sensors, GNSS sensors, and processing units, enhancing our offering. While our sensors are mainly utilized within our systems, we also support OEMs with ROS2 interface capabilities.

SCHENK PROCESS Qlar

Weighing your bulk materials with efficiency and precision

Qlar, formerly known as Schenck Process, is a leading global supplier and technology partner of sustainable products, integrated solutions, and services for process critical bulk materials applications

Schenk Process Qlar current target industries: infrastructure, energy, chemicals, performance materials and alternative fuels. The product range includes solutions for industrial, weighing, feeding, conveying, milling and grinding, and related digital applications of the CONiQ product family.

INDURAD RADAR SENSOR PRODUCT RANGES

INDURAD RADAR SYSTEM PRODUCT RANGES

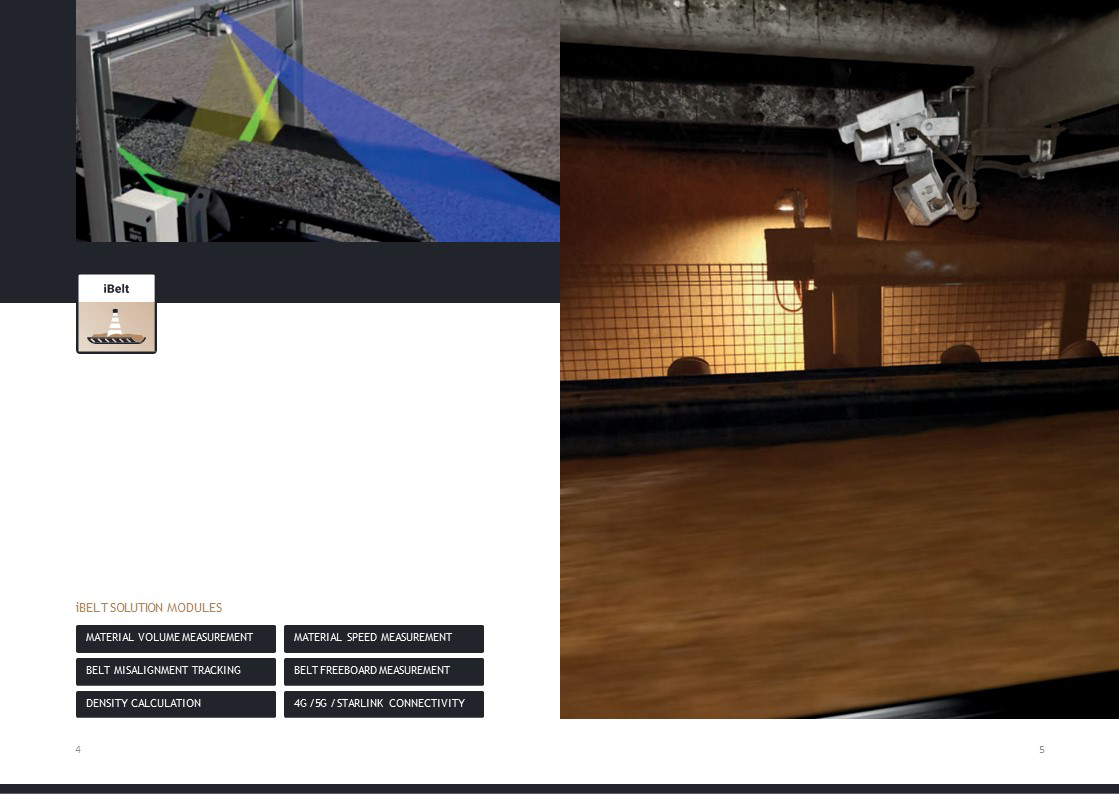

BULK MATERIAL FLOW & BELT MONITORING -i Belt

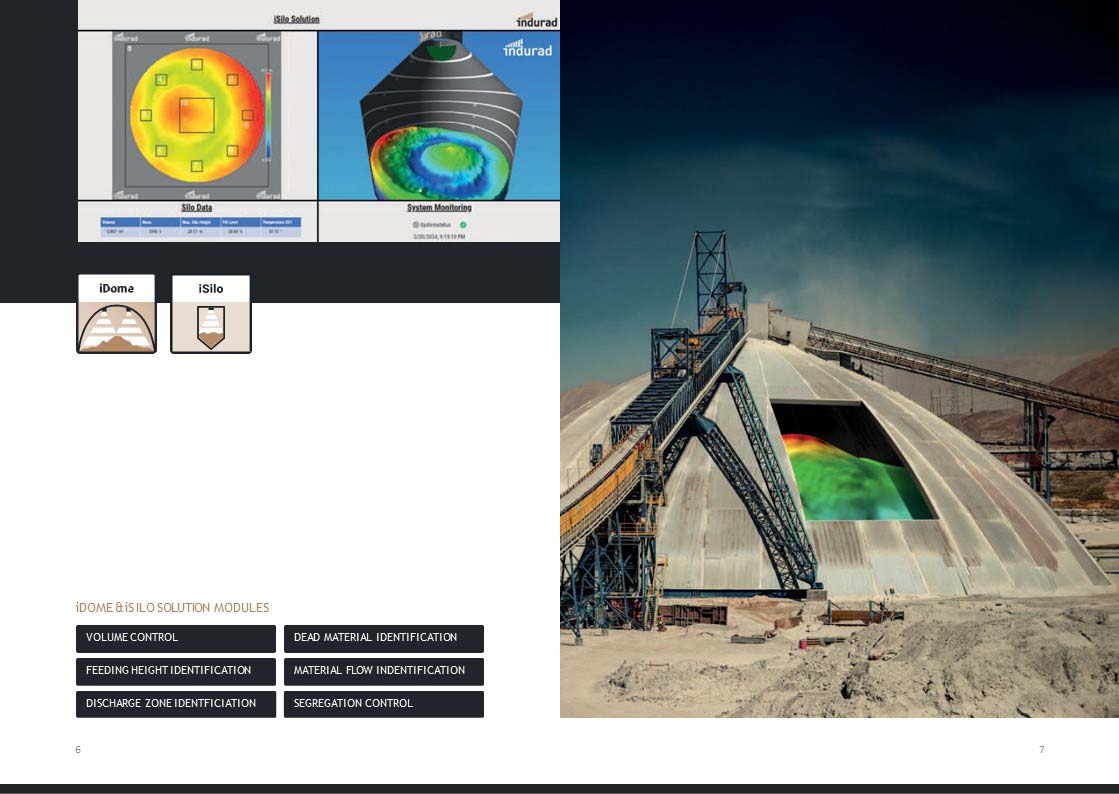

VOLUME MEASUREMENT & FEEDER DRWA CONTROL -i Dome & i Silo

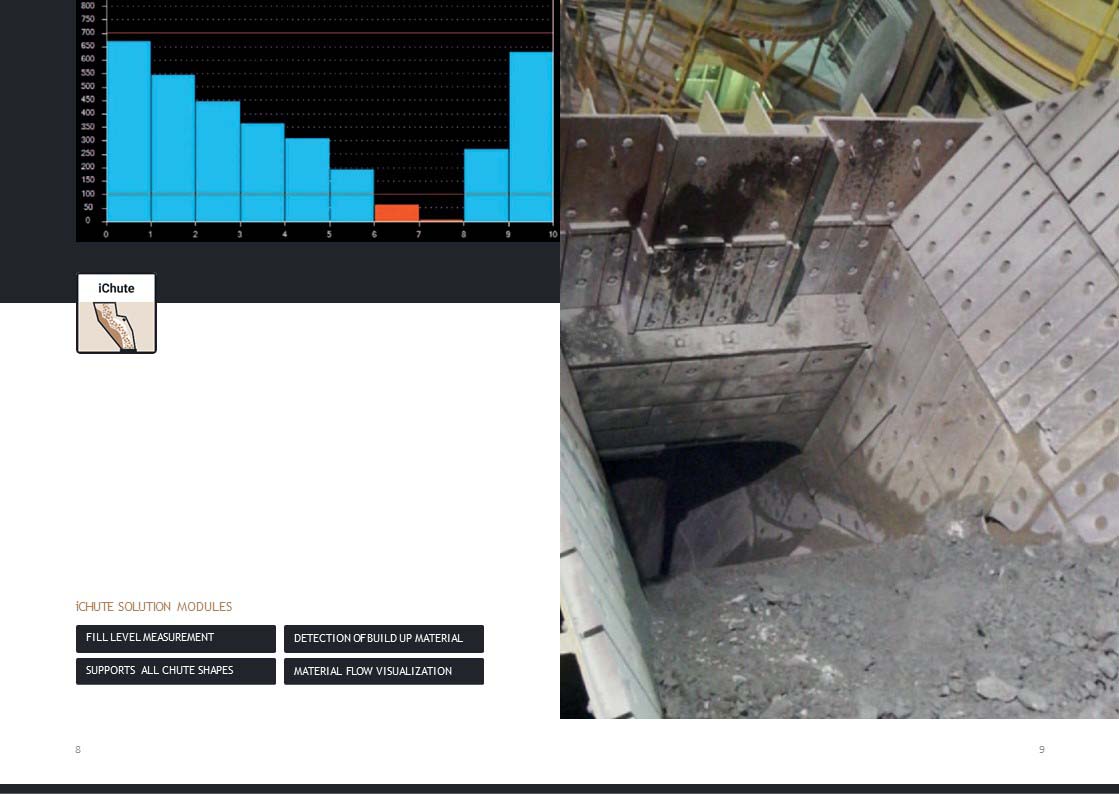

LEVEL CONTROL & BLOCKAGE DETECTION -i Chute

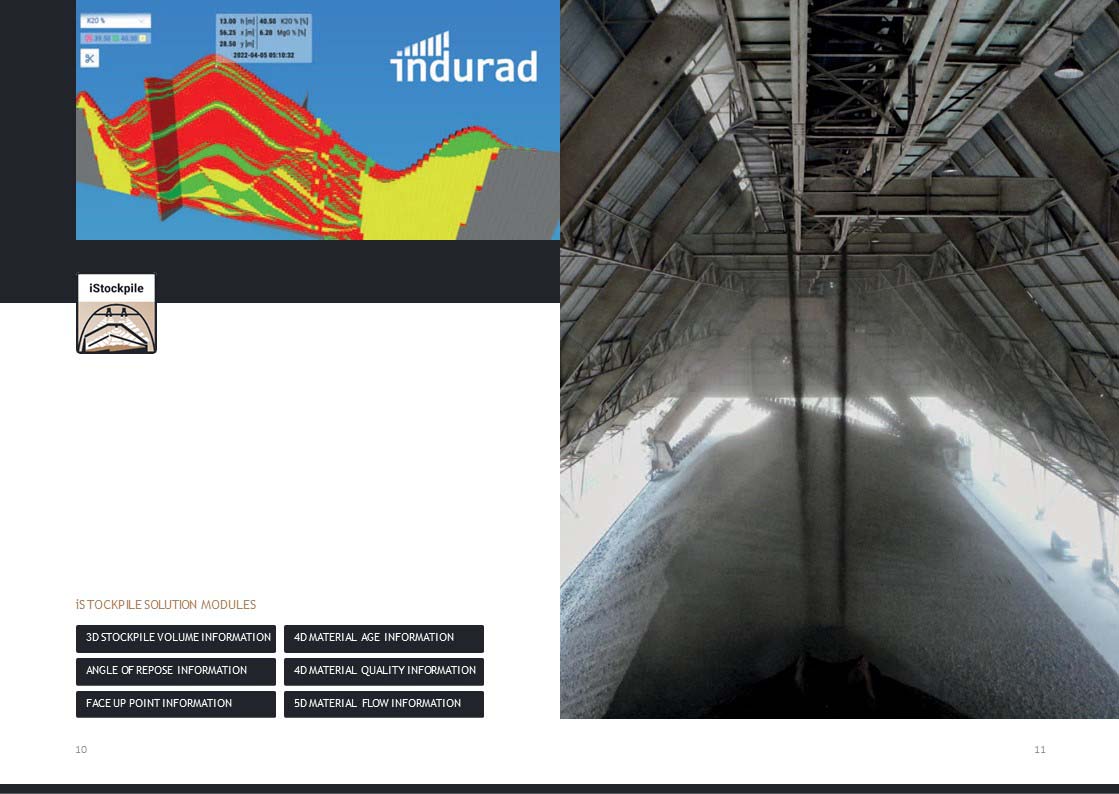

3D INVENTORY CONTROL & PROCESS IMPROVEMENTS-istokepile

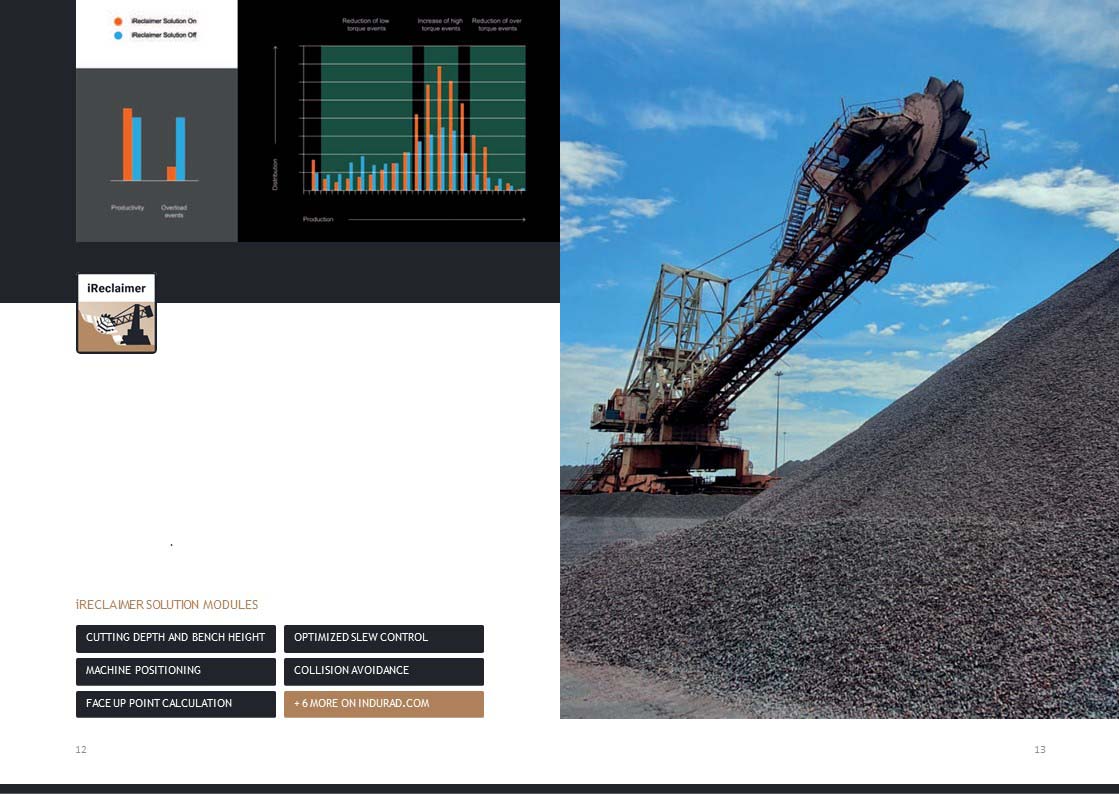

MACHINE CONTROL & PRODUCTIVITY BOOST- iReclaimer

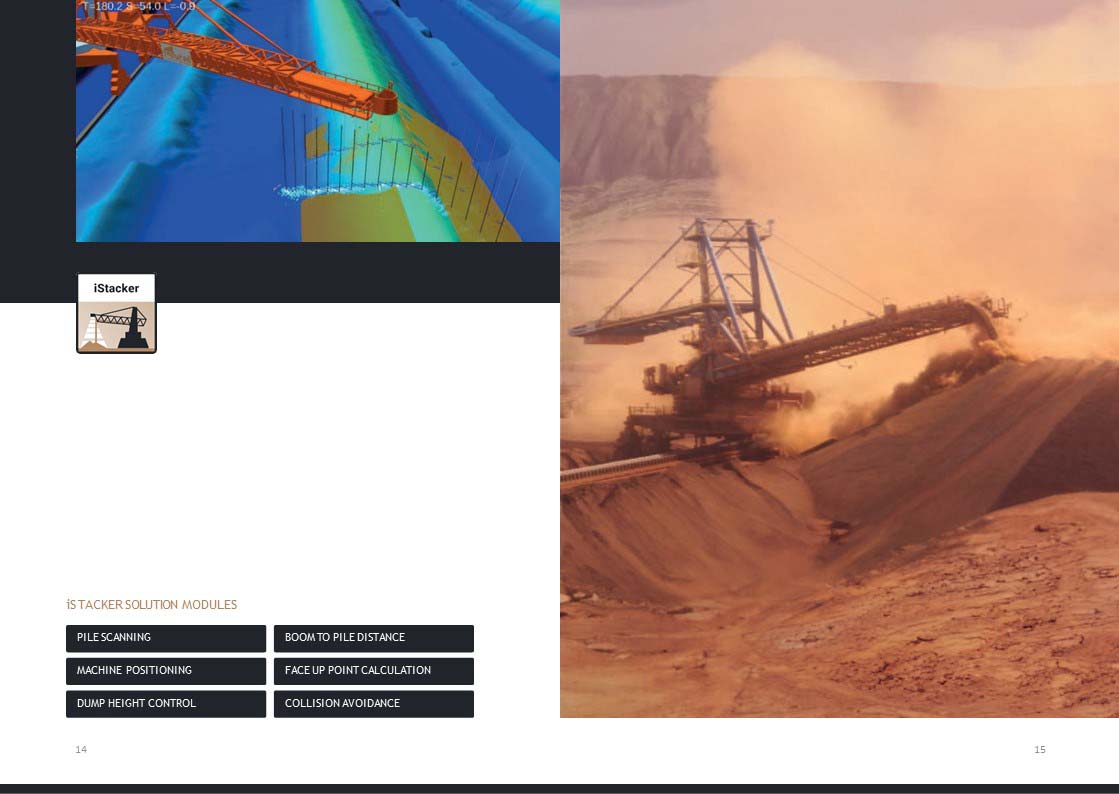

STACKING ASSISTANCE & INVENTORY CONTROL-i stacker

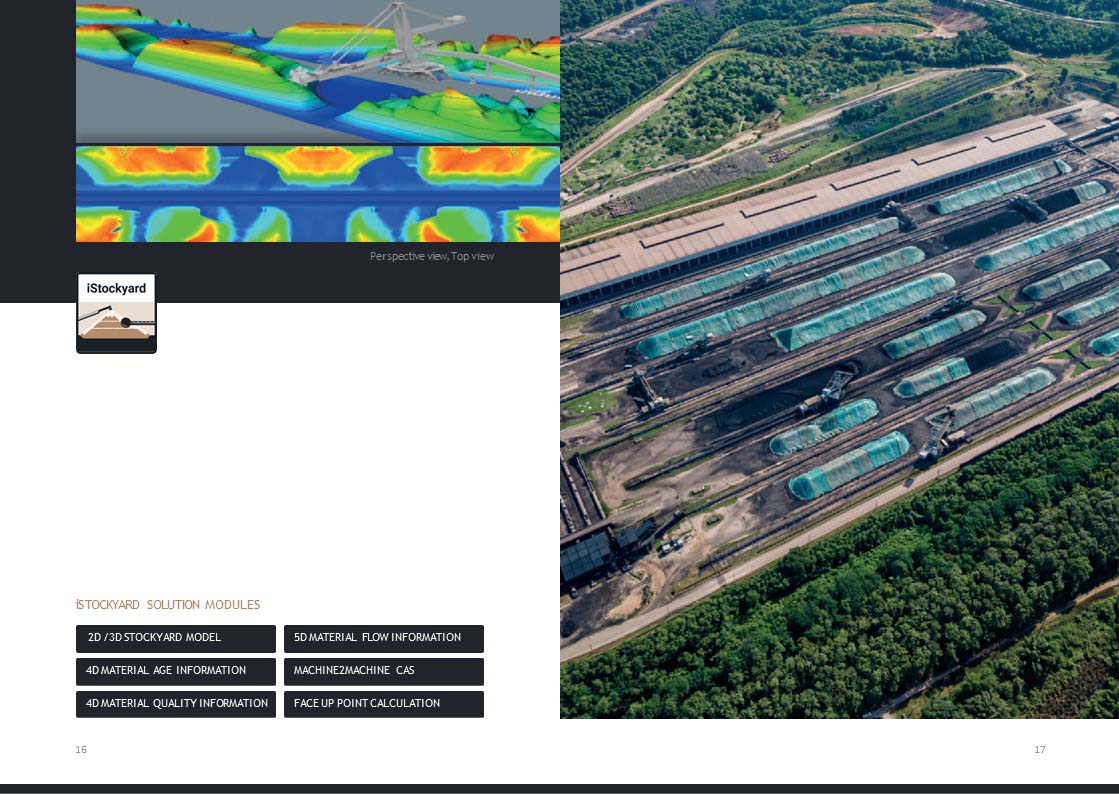

FULL VISIBILITY OF YOUR STOCKYARD -i stockyard

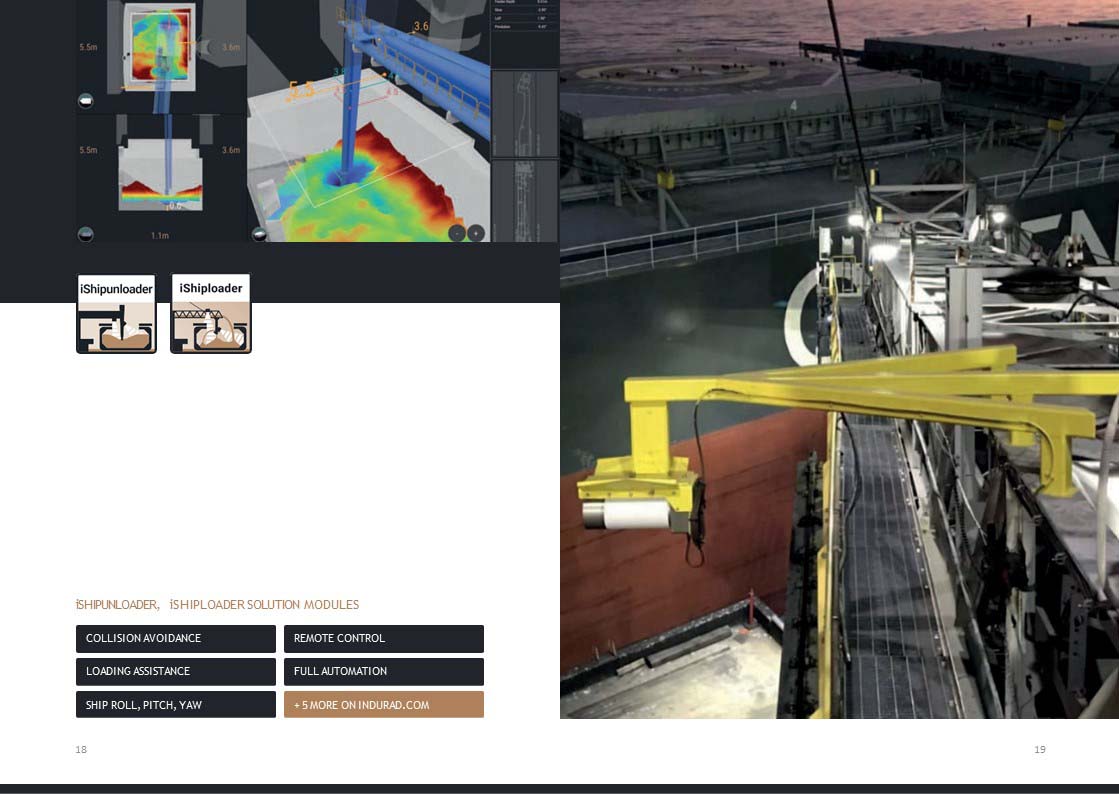

COLLISION AVOIDANCE, REMOTE CONTROL & AUTOMATION - ishiploader & i shipunloader

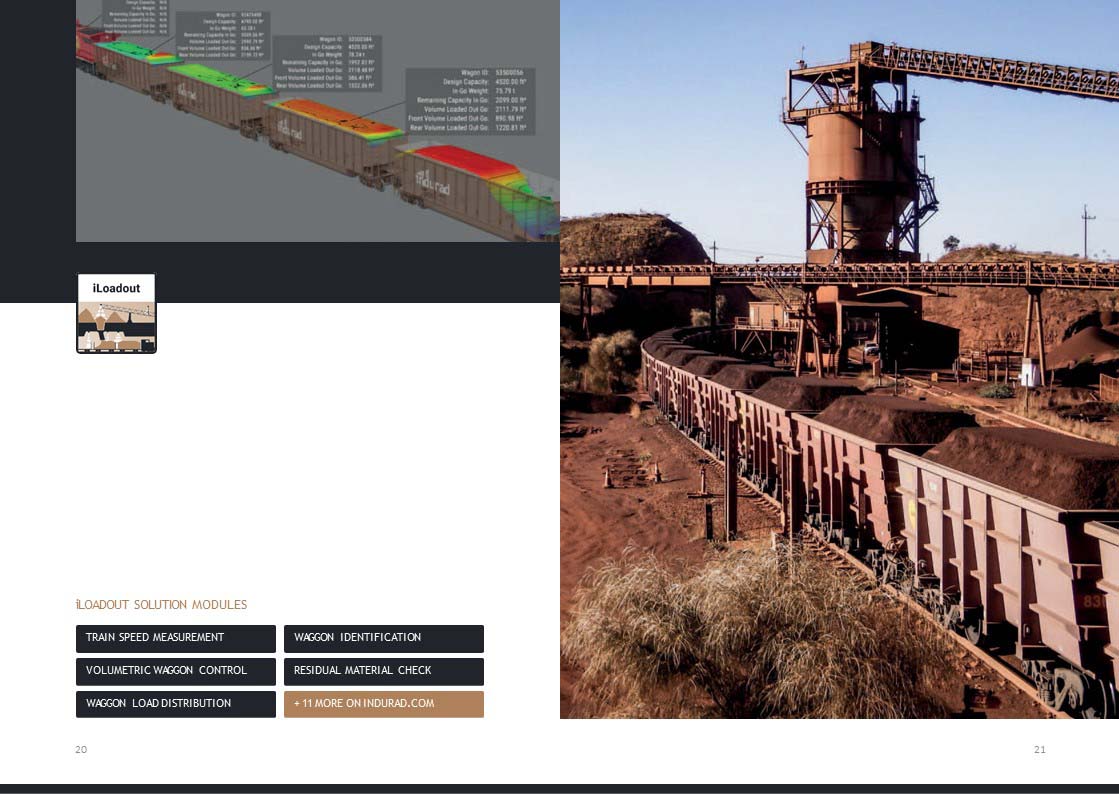

ADVANCED PROCESS CONTROL: HIGHER SETPOINT, LESS DEVIATION -iloadout

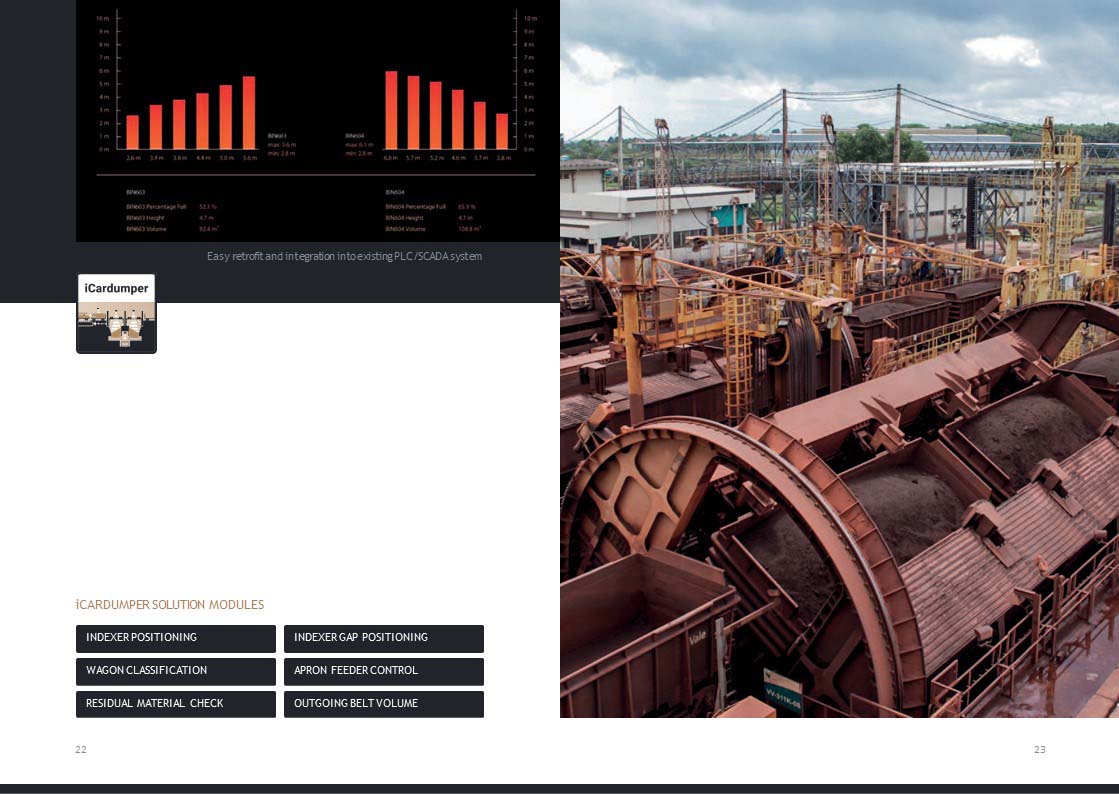

IMPROVE RELIABILITY & AVAILABILITY IN INLOAD - icardumper

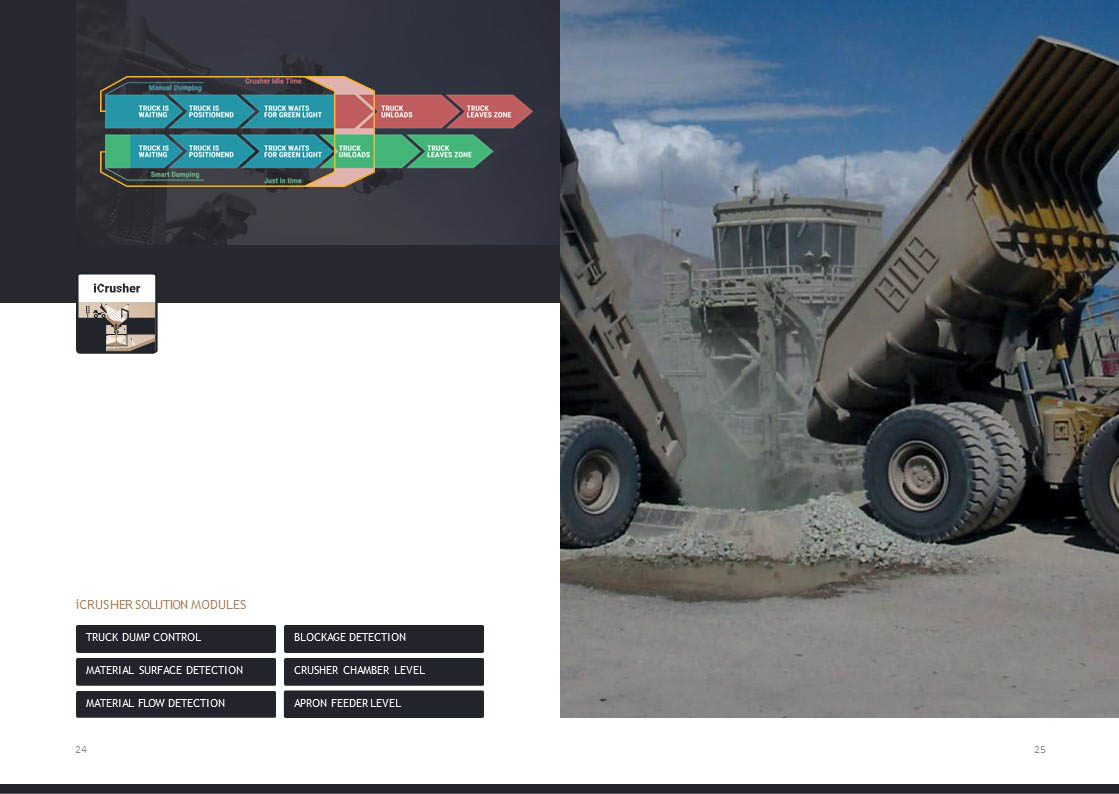

PRIMARY, SECONDARY & TERTIARY CRUSHERS - icrusher

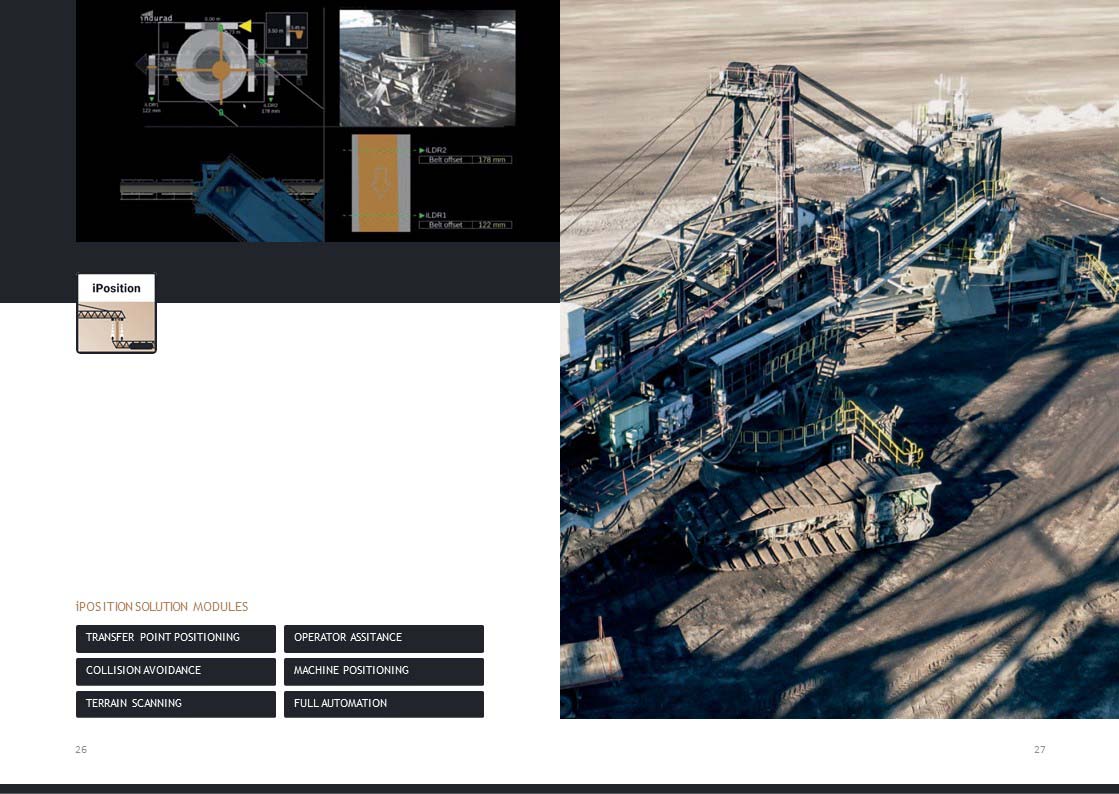

REAL-TIME MACHINE & IPCC POSITIONING - iposition

SCHENCK PROCESS (Qlar )PRODUCTS & SOLUTIONS

- WEIGHING

- CONVEYING

- CONDITION MONITORING

- FEEDING

- FILTERATION

- MILLING & GRINDING

- SMART PROCESS CONTROL

- SOFTWARE AUTOMATION

Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum.

Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast. Far far countries Vokalia and Consonantia, parated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast. Far far countries Vokalia and Consonantia, parated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast. Far far countries Vokalia and Consonantia, parated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast. Far far countries Vokalia and Consonantia, parated they live in Bookmarksgrove right at the coast

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum.

Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum.

Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum.

Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi. Aenean vulputate eleifend tellus. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Quisque rutrum.

STATIC AND DYNAMIC SACLES

MECHNICAL CONVEYORS