GasAnalyzers

ONLINE PROCESS ANALYZERS

Teledyne | AAQMS Analyzers

SYSTEMS EQUIPMENT provides effective solutions for Ambient Air Quality Monitoring analyzers for gas analysis.

Teledyne API (TAPI) designs and builds precision air quality and industrial gas monitoring instrumentation at our factory located in San Diego, California, USA. Teledyne API AQMS analyzers comply with U.S. Environmental Protection Agency (EPA), European Union (EU) and other global regulatory agencies for the measurement of criteria pollutants, some of which are NOX, SO2, CO, O3, PM10 & PM2.5

Technology

!

Gas Filter Correlation

CO, CO2

!

UV Absorption

O3

!

Non-Dispersive Infrared (NDIR)

SiF4, SiF3, CO, CO2, CF4, SF6, NF3, WF6 and other species

!

Paramagnetic

O2, CO2

!

Ultraviolet (UV) Fluorescence

SO2, H2S, TRS, TS

!

Cavity Attenuated Phase Shift Spectroscopy

NO, NO2

!

Chemiluminescence

NO, NO2, NOx, NOY, NH3, O3

!

Continuous Real-time Particulate Matter Mass Monitoring

PM2.5, PM10, PM10-2.5, PM1, PM total

!

Flame Ionization Detector

THC, CH4, NMHC

NITGROGRN COMPONENT ANALYZERS

Teledyne API produces a wide range of analyzers for the measurement of Nitrogen compounds, including those that measure ‘True NO2’.

All T Series analyzers offer two front-panel USB ports, an advanced touch screen full color display, customizable user interface with predictive maintenance alerts, one-touch real-time graphing, and multiple language support. All of our analyzers are designed meet the rigorous demands of ambient air quality, stack, or industrial process gas monitoring.

Model : CAPS Trace-level NO2 Analyzer

Range : 0-5 ppb / 0-1,000 ppb

Model : N200 - NO, NO2, NOx

Range : 0-5 ppb / 0-1,000 ppb

Model : T200M - Mid Level NO, NO2, NOx Analyzer

Range : 0-1 ppm / 0-200 ppm

Model : N200M - Mid Level NO, NO2, NOx

Range : 0-1 ppm / 0-200 ppm

Model : T200H - High Level NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : N200H - High Level NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : T200P - True NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : N200H - High Level NO, NO2, NOx

Range : 0-50 ppb / 0-4,000 ppb

Model : T200U - Trace Level NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T200U NOY - Trace Level NO-NOy

Range : 0-5 ppb / 0-2,000 ppb

Model : T200UP - Trace Level, True NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T201 - NH3, NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : N201 - NH3, NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T500U - Trace Level, True Direct NO2

Range : 0-5 ppb / 0-1,000 ppb

Model : N500 - True NO2, NOx, NO

Range : 0-5 ppb / 0-1,000 ppb

OXYGEN COMPONENT ANALYZERS

Teledyne API produces a wide range of analyzers for the measurement of Nitrogen compounds, including those that measure ‘True NO2’.

All T Series analyzers offer two front-panel USB ports, an advanced touch screen full color display, customizable user interface with predictive maintenance alerts, one-touch real-time graphing, and multiple language support. All of our analyzers are designed meet the rigorous demands of ambient air quality, stack, or industrial process gas monitoring.

Model : CAPS Trace-level NO2 Analyzer

Range : 0-5 ppb / 0-1,000 ppb

Model : N200 - NO, NO2, NOx

Range : 0-5 ppb / 0-1,000 ppb

Model : T200M - Mid Level NO, NO2, NOx Analyzer

Range : 0-1 ppm / 0-200 ppm

Model : N200M - Mid Level NO, NO2, NOx

Range : 0-1 ppm / 0-200 ppm

Model : T200H - High Level NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : N200H - High Level NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : T200P - True NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : N200H - High Level NO, NO2, NOx

Range : 0-50 ppb / 0-4,000 ppb

Model : T200U - Trace Level NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T200U NOY - Trace Level NO-NOy

Range : 0-5 ppb / 0-2,000 ppb

Model : T200UP - Trace Level, True NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T201 - NH3, NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : N201 - NH3, NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T500U - Trace Level, True Direct NO2

Range : 0-5 ppb / 0-1,000 ppb

Model : N500 - True NO2, NOx, NO

Range : 0-5 ppb / 0-1,000 ppb

HYDROCARBON ANALYZERS

AIR DEMAND ANALYZER

930

PARTICULATE ANALYZERS

SULFUR PIT ANALYZER

881

Model : CAPS Trace-level NO2 Analyzer

Range : 0-5 ppb / 0-1,000 ppb

Model : N200 - NO, NO2, NOx

Range : 0-5 ppb / 0-1,000 ppb

Model : T200M - Mid Level NO, NO2, NOx Analyzer

Range : 0-1 ppm / 0-200 ppm

Model : N200M - Mid Level NO, NO2, NOx

Range : 0-1 ppm / 0-200 ppm

Model : T200H - High Level NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : N200H - High Level NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : T200P - True NO, NO2, NOx

Range : 0-5 ppm / 0-5,000 ppm

Model : N200H - High Level NO, NO2, NOx

Range : 0-50 ppb / 0-4,000 ppb

Model : T200U - Trace Level NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T200U NOY - Trace Level NO-NOy

Range : 0-5 ppb / 0-2,000 ppb

Model : T200UP - Trace Level, True NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T201 - NH3, NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : N201 - NH3, NO, NO2, NOx

Range : 0-5 ppb / 0-2,000 ppb

Model : T500U - Trace Level, True Direct NO2

Range : 0-5 ppb / 0-1,000 ppb

Model : N500 - True NO2, NOx, NO

Range : 0-5 ppb / 0-1,000 ppb

CARBON COMPONENT ANALYZERS

H2S IN HYDROCARBON

ADI 2045 TI

SULFUR COMPONENT ANALYZERS

NIR ANALYZER

XDS Process Analyzer

GAS CALIBARATOR

202X PROCESS ANALYZER

OXYGEN COMPONENT ANALYZERS

ZERO AIR GENERATORS

O3 Ozone Analyzer

O3 Ozone - T265 ( 0-100 ppb / 0-2,000 ppb ) O3 Ozone- T400 0-100 ppb / 0-10 ppm O3 Ozone -N400 0-100 ppb / 0-10 ppm O3 Ozone - 430 0-100 ppb to 0-20,000 ppb O2 Oxygen -T802 0-100% (Paramagnetic) O2 Oxygen -N802 0-1% / 0-100%

TF16-EX-HT-N

A scattered light dual channel turbidity sensor for monitoring trace oil in water or undissolved hydrocarbons in the low ppm range

SPECILAITY GAS ANALYZERS

TF16-EX-N

A scattered light dual channel turbidity sensor for filter monitoring or free water content in refined fuels

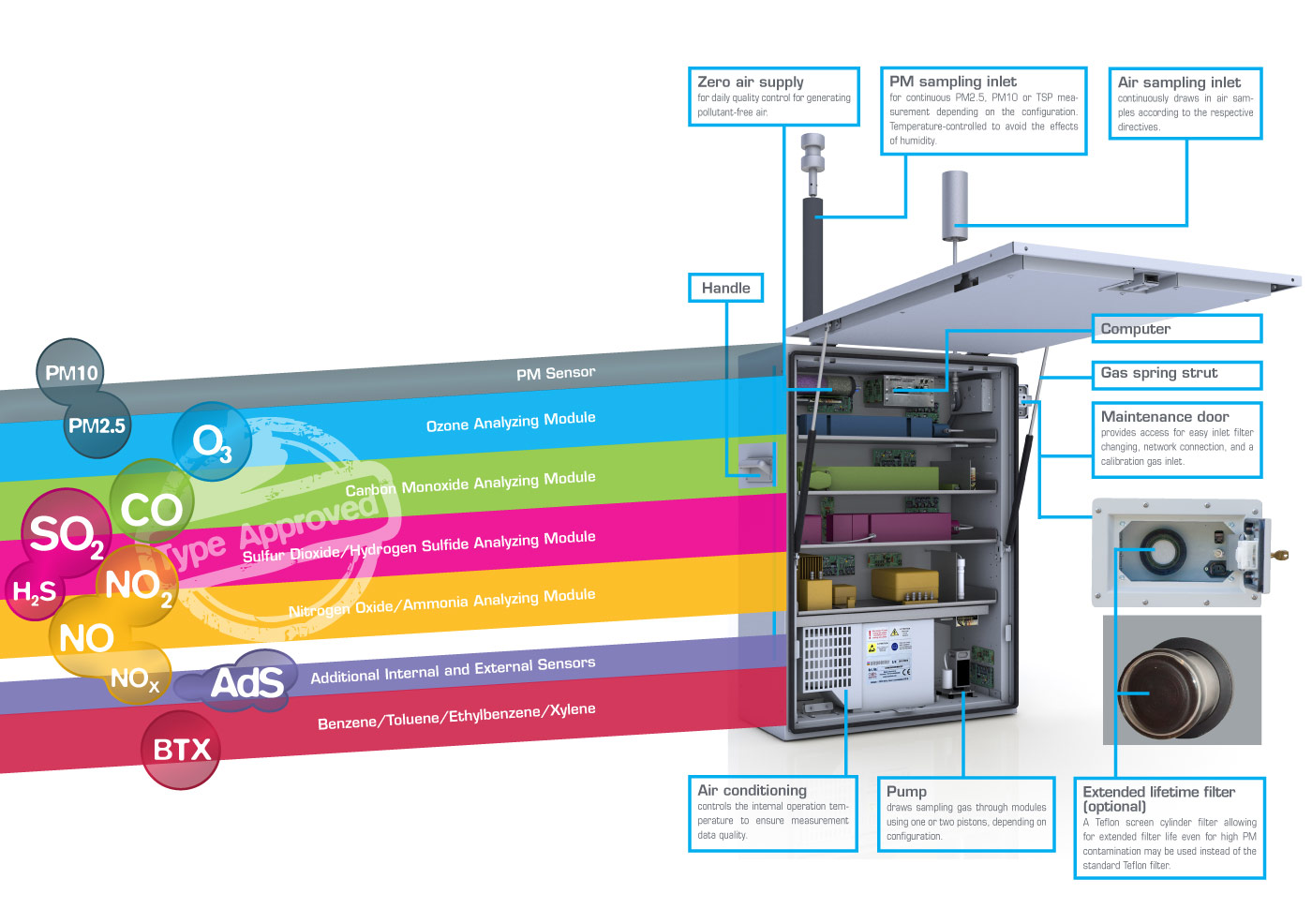

AAQMS( Ambient Air Quality Monitoring Systems ) ANALYZERS OFFERED | SYSTEMS EQUIPMENT

WE HAVE WIDE RANGE ANALZYERS IN AAQMS ( Ambient Air Quality Systems ) SYSTEMS .SOME OF THEM ARE MENTIONED BELOW .FOR MORE DETAILS PLEASE CONTACT US .

- CO ANALYZER

- SO2 ANALYZER

- H2S ANALYZER

- NO-NOX ANALYZER

- NH3 ANALYZER

- O3 ANALYZER

- HC BTX ANALYZER -BENZENE,TOULENE & XYLENE

- CO 2 ANALYZER

- TSP -ANALYZER

- PM 10 -ANALYZER

- PM 2.5-ANALYZER

- ALL IN ONE METROLOGICAL SENSOR

- PORTABLE AAQMS ANALYZERS

Carbon monoxide (CO) is monitored continuously by analyzers that operate on the infrared absorption principle. Ambient air is drawn into a sample chamber and a beam of infrared light is passed through it. CO absorbs infrared radiation, and any decrease in the intensity of the beam is due to the presence of CO molecules. This decrease is directly related to the concentration of CO in the air. A special detector measures the difference in the radiation between this beam and a duplicate beam passing through a reference chamber with no CO present. This difference in intensity is electronically translated into a reading of the CO present in the ambient air, measured in parts per million (ppm).

Sulfur dioxide (SO2) is measured continuously by instruments using the fundamental principle of fluorescence.

UV fluorescence principle, coupled with a state of the art user interface to provide easy, accurate, and dependable measurements of low level SO2.

Exceptional stability is achieved with the use of an optical shutter to compensate for PMT drift and a reference detector to correct for changes in UV lamp intensity. A hydrocarbon ‘kicker’ and advanced optical design combine to prevent inaccuracies due to interferents.

All T Series instruments offer an advanced color display, capacitive touch screen, intuitive user interface, flexible I/O, and built-in data acquisition capability. All instrument set up, control and access to stored data and diagnostic information is available through the front panel

Fluorescent analyzers irradiate an ambient air sample with ultraviolet light at 213.8 nm. Sulfur dioxide gas molecules absorb a portion of this energy, then re-emit the energy at a characteristic wavelength of light. This light energy emitted by SO2 molecules is sensed by a photomultiplier tube and converted to an electronic signal proportional to the concentration of SO2present.

Continuous monitoring of nitrogen dioxide (NO2) is based on a chemiluminescent reaction between nitric oxide (NO) and ozone (O3). When these two gases react, light energy at a specific wavelength is produced. In the monitor, ambient air is drawn along two paths. In the first path, the air is reacted directly with ozone, and the light energy produced is proportional to the amount of NO in the air. In the second path, the air is reacted with ozone after it passes through a catalytic reduction surface. The reduction surface converts NO2 to NO and the light energy produced is a measure of the total oxides of nitrogen in the air sample. The electronic difference of these two signals yields the concentration of NO2. All concentrations for NO2 are given in parts per million (ppm).

Ozone is measured continuously by analyzers that operate using the monochromatic ultraviolet absorption spectrophotometry principle. As ultraviolet light at 253.7 nm is passed through the optic bench, a fixed quantity of “zero air” and ambient air are drawn into the bench. The intensity of the ultraviolet radiation traversing the optics bench is attenuated by the ozone present in the ambient sample. This attenuated signal is detected and compared with the unattenuated signal from the “zero air” cycle. This difference in intensity is electronically translated into a reading of ozone present in the ambient air.

Using gas chromatography, measures the amount of Benzene, Toluene, Ethylbenzene and Xylenes in the air from sub-ppb levels up to 1,000 ppb.

Miniaturization, sensitivity, mobility and flexibility are the main features of the instrument .It uses a port valve with a single absorbent trap and a metallic 0.28 mm ID column. It has a programmed gradient temperature of the oven and pressure/flow control of the carrier gas by a piezo valve.

The detection is made with a Flame Ionisation Detector for high stability and an excellent sensitivity. Its minimum detection limit is as low as 50 ppt for Benzene in ambient air. An H2 supply for FID and carrier gas is sufficient, so there is no N2 required.

It provides comfortable user friendly utilities to recalculate, calibrate and export data and to configure the measurement. The software allows the calculation of retention time, area, mass or concentration profiles in any measuring unit.

Ethernet connectivity provides efficient remote access, allowing the user to download measurement information directly from the instrument without having to be on-site.

Special Features and Applications

- A GC/FID for automatic monitoring of BTEX in air, water and soils

- Beverage and food industry

- For monitoring in urban and non urban areas as well as on fence line

- Ethernet connectivity for efficient remote access

- Highly stable FID

- Completely automated on-line analyser

Options

- Styrene and Cyclohexane additionally

- Additional communication protocols

- CALIB for A34022

- Automatic validation and auto calibration

- Hydrogen and air zero generator

- Modem support and PC anywhere

- 6 analog outputs 4-20 mA or 0-10 V

The shorthand PM10 is defined as particulate matter with an aerodynamic diameter less than or equal to a nominal 10 micrometers. The reference method for the measurement of atmospheric particulate matter as PM10 is based on selection of PM10 particles by internal separation, followed by filtration and gravimetric determination of the PM10 mass on a filter substrate. Selection of PM10 is accomplished by a size selective head that is symmetrical designed and contains nine circular acceleration nozzles. By virtue of their larger momentum, particles greater than 10 micron aerodynamic diameter impact onto a greased impaction shim. The PM10 particles smaller than 10 microns are carried vertically upward by the air flow and down 16 vent tubes to a 8-by-10 inch quartz-fiber filter, where they are collected.

Automatically measures and records airborne particulate concentration levels (in milligrams or micrograms per cubic meter) using the industry-proven principle of beta ray attenuation.

FEATURES

- U.S. EPA Equivalent Method for PM10, PM2.5, and PM10-2.5 monitoring

- Long term unattended remote operation of up to 60 days between site visits

- Very low operating costs

- Automatic Span Calibration checks

- Fast and easy field audits using common FRM audit tools

- Bench top or equipment rack mounting in mobile or stationary shelters

- Rugged anodized aluminum, stainless steel, and baked enamel construction

- Highly accurate, reliable, and mechanically simple flow system

- Hourly filter advances minimize effects on volatile compounds

- Advanced Smart Heater technology precisely controls sample relative humidity

- Integrated datalogger allows the connection of up to two multi-parameter meteorological sensors

- Data retrieval through RS-232 or RS-485 serial ports using direct PC connections, or digital data collection systems

All-in-one weather sensors measure multiple parameters. For example, these may include wind speed and direction, precipitation, barometric pressure, temperature, and relative humidity. (For sensor-specific measurements, reference the chart below.) These multi-function sensors have no moving parts.

COMPACT AAQMS ANALYZER

COMPACT AAQMS ANALYZER

World Class Brands | Customer Satisfaction

Compact AAQMS Analyzer | Air Quality Monitoring Analyzers| Airpointer

We provide process analyzers for liquid analysis .Liquid analyzers are the used in different sections of the industry .We are provide the best brands with wide range of operation requirements . For more details contact us .

Portable Flue Gas Analyzers

Portable Flue Gas Analyzer

World Class Brands | Customer Satisfaction

Portable Flue Gas Analyzer | SYSTEMS EQUIPMENT

Portable Flue Gas Emissions Analyzer with Capitalize Superior and Accuracy

As tough as cast iron, but as easy to operate as a smartphone – that‘s what Wöhler‘s new Flue Gas Emssions Analyzer feels like in your hand. A tap of your finger on the Wöhler A 550 INDUSTRIAL is all that is required to perform a complete analysis and inspection of boilers and burners. The Flue Gas Emissions Analyzer is designed to be used in tough industrial heat processes. The in-stack stainless steel sinter-filter probe protects the analyzer against heavy dust loads.