Mechanical Solutions

Screw Compressors

Under the MYCOM brand, Mayekawa’s compressors are used worldwide in industrial refrigeration and freezing, heat pumps, and gas markets. Our compressors leverage thermal technology developed through years of experience to consistently provide high quality. We also offer a full lineup of environmentally-friendly compressors that use natural refrigerants. We have received high evaluations for gas compressors through our experience with helium, hydrogen, water vapor, chlorine, hydrogen chloride, hydrogen sulfide (excluding oxygen and acetylene), and other gases in dealing with resource- and energy-related problems. MYCOM compressors are highly trusted, having been used globally for over 70 years.

Steam Turbines /Hydraulic Turbines

FTM has developed its product range through a standardized modular approach, in order to meet any customer’s need with the same top-class reliability, efficiency and flexibility.

Type of machines described above are typical arrangement of different standard modules which can be combined in several possible solutions.

For example, the HIC / DL turbine is made by one HI module (High pressure and Intermediate pressure sections combined in the same cylinder) + one DL module (Double flow Low pressure cylinder). On the other hand, a backpressure turbine with reheat can be obtained by utilizing only an HI module.

Thanks to its long and diversified experience in hydro power machinery, today Franco Tosi Meccanica is able to cover a full range of market applications for the power generation industry.

PELTON FRANCIS KAPLAN VALVES

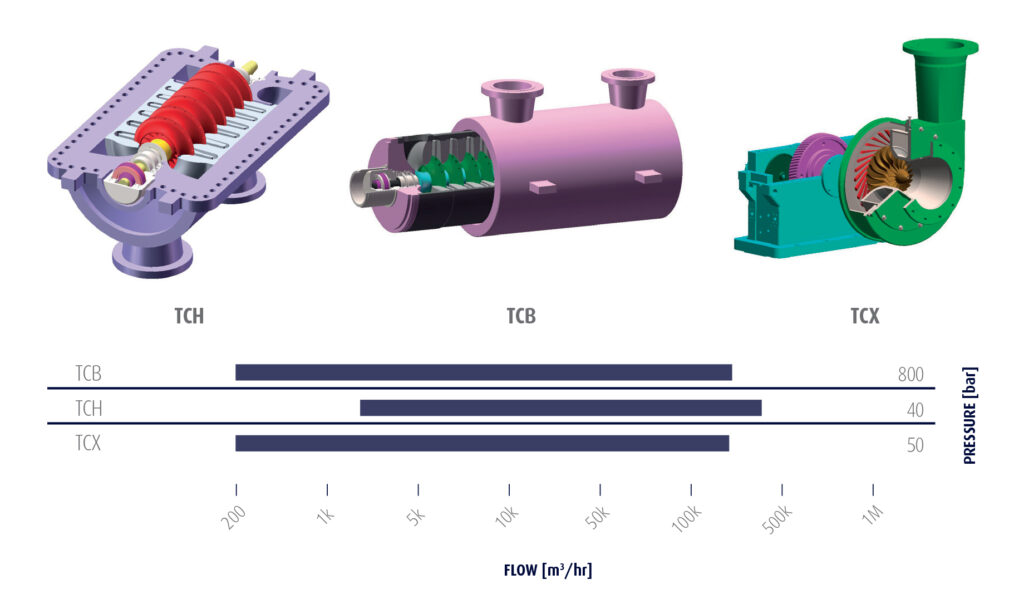

Centrifugal Compressors

Beyond the vast range of Power Generation machinery, Franco Tosi Meccanica historically delivered many compression trains, to serve also the process industry. Since early Sixties, tens of centrifugal compressors left the Legnano workshop, to reach the destination plants in the world, where – in many cases – they are still running for the production of hydrocarbon derivates, industrial gases, polymers and energy. Nowadays, by means of strategic sinergies and the contribution of experienced engineers and partners, we offer to the Oil&Gas, Industrial Gases and Energy markets, a broad, portfolio of equipment and services. Performances, reliability, flexibility are our targets in each project, from the initial design, to the operation, to the whole lifecycle.

End-users of the Up-Mid-Downstream, power and industrial markets can access to the Italian quality, flexibility and reliability, working with responsive engineering team from the early stage of a project to the whole lifecycle of their compression facilities.

The supply can span from the bare machine, designed and manufactured to the most stringent engineering specification, to the complete compression train, featuring the prime mover, the auxiliary systems, the control, safeguarding and monitoring equipment, fully preassembled and tested to ensure a simple, safe and reliable installation matching the schedule of your project. The sizing range features three main families of machines, each of them selectable for different application, according the process conditions.

Mixers

When it comes to mixing solutions, no two scenarios are the same. The type, speed and design of an industrial mixer is contingent on the input phases of the solutes and solvents. Whether it’s liquid–liquid, liquid-solid, solid suspension, or any number of other applications, each has intricate needs that require flexible solutions.

Agitators

An agitator is a device or mechanism to put something into motion by shaking or stirring. There are several types of agitation machines, including washing machine agitators (which rotate back and forth) and magnetic agitators (which contain a magnetic bar rotating in a magnetic field).ulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Injection Quills

The purpose of Injection quills is to introduce corrosive chemicals (medium to highly corrosive) into a pipeline without damaging the pipe wall or the side port at the exact point of injection.

Chemical injection quills ensure that there is an even dispersion of chemicals into the pipeline’s center, which avoids channeling down the pipe wall of the chemical. Both the stinger and the body are constructed of materials that are chemical resistant alloys or plastics (Kynar, 316 SS, Hastelloy C-276 or PVC). Each injection quill unit of Crystal Industrial comes in total with an integral removable ball check with spring loaded, to avoid flow of the injected chemical passing into the main flow when the system is shut down.

In the past, chemical injection quills have been little more than a piece of tube extending into a pipe. This design is vulnerable to erosion-corrosion and cavitation in the piping due to vortex shedding and other hazards. Moreover, often these quills and the piping just downstream are not properly inspected. Due to which there have been numerous cases of damage to the piping just after these quills.

Crystal’s chemical Injection Quills have a tapered shape which reduces the effects of vortex shedding, thus vastly reducing the likelihood of erosion-corrosion, cavitation, and quill fatigue cracking.

Each quill is custom designed for a specific application keeping in mind the vortex shedding, erosion, vibration, resonance and strength of the attachment to the pipe, according to ASME rules. The quill can be supplied with one or two root valves.

Pressure Vessels

Systems Equipment Supplies high reliability, high integrity Pressure Vessels, Towers & Columns in practically all engineering metals used by process industry. We supplies pressure vessels that are designed to operate safely at a specific pressure & temperature .We have approved by ASME ‘U’ & ‘R’ Stamp for the manufacture of pressure vessels as per code stamp.We provide pressure vessel under reputed international inspection agencies like LLOYDS, TUV, BUREAU VERITAS, AKER KVAERNER, UHDE, TOYO. The type of vessels offered by crystal are :

- Exotic metal cladded Pressure Vessels

- Accumulator shells

- Filters

- Columns

- Cladded drums

PIPE CLADDING

TEE CLADDING

ELBOW CLADDING

FLANGE CLADDING

CLADED PIPE & FITTING

Our cladded pipes comply with the most demanding standards of strength, corrosion resistance and cost effectiveness. Generally the outer part of the pipe is made of carbon steel to withstand the inner pressures, while the inner high alloyed cladding of the pipe is meant to protect against corrosion.

We offer two types of cladding process :

- Metallurgically cladded plates

- Mechanically bonded pipes

- FLAGE CLADDING

- PIPE CLADDING

- ELBOW CLADDING

- TEE CLADING

Our Partners